Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

What is quality management?

Quality management is a set of processes that help you anticipate, control, and respond to potential product quality issues. Processes such as field failure reports, nonconformance, and corrective/preventative actions provide efficiency and traceability. Quality and engineering have a closed-loop change process to improve product designs.

Closed-loop quality management

Improve quality processes throughout your product development cycle and supply chain.

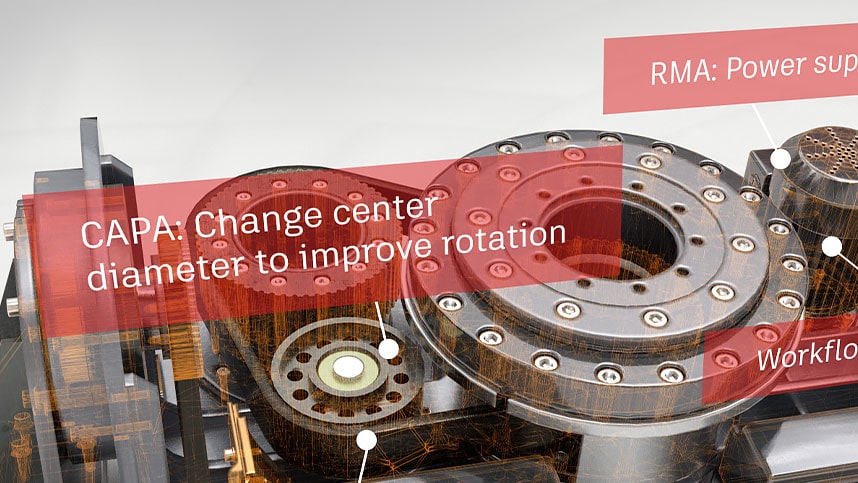

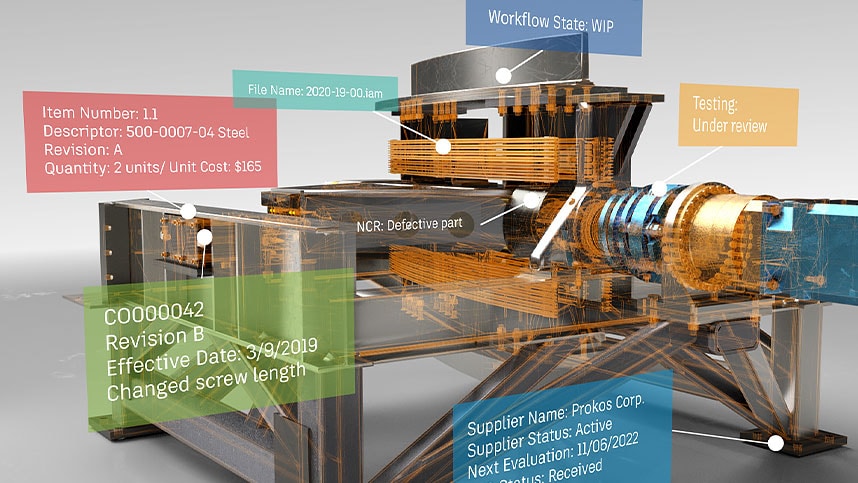

Closed-loop, linked quality processes from return to change order

Prevent and rapidly respond to product design issues and supplier problems. Get a complete view of your quality data and critical processes from nonconformance to return merchandise authorizations (RMA), corrective and preventative actions (CAPA), failure mode and effect analysis (FMEA), supplier quality action report (SCAR), and engineering change.

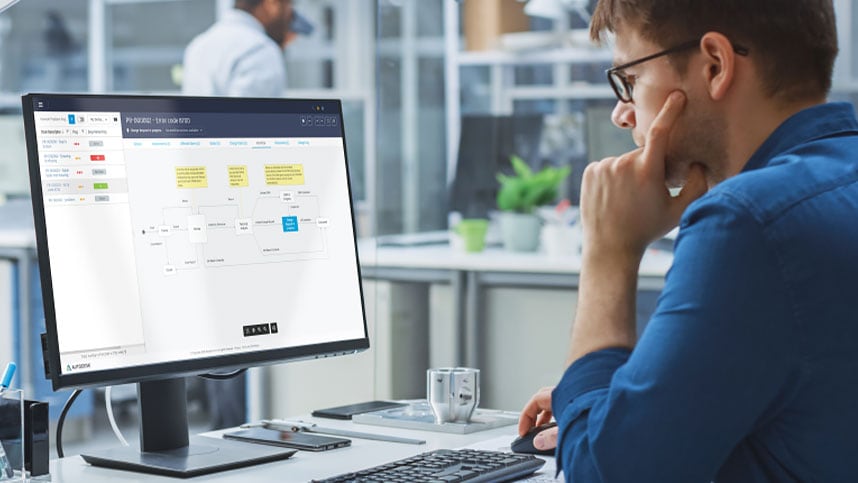

Configurable process management workflows

Quality management process workflows are provided with PLM that you can easily configure to match your organization’s needs, including:

- Nonconformance incident reporting, analysis, and disposition

- RMA return requests, approval, and repair

- CAPA compliance requirements

- Change requests and change orders

Help with compliance and traceability

In-progress or completed processes related to change, quality, or another discipline are fully traceable. Compliance audits can be tied to ISO documents for traceability if you are in a highly regulated industry. Throughout quality process workflows, the product item affected is referenced to maintain connection.

- Changes are documented with who created them and when, and any modifications

- Details include who signed off on each stage and when

- A single source of data required to meet auditing and compliance requirements

Improving the quality of your products with PLM

Collect and analyze quality data

Quality management workspaces give you a central location for quality data and built-in reporting charts and graphs to help you assess quality trends and prevent failures before they occur.

Automated quality-related tasks

Automated quality workflows send tasks, reminders, and escalations to assigned team members for outstanding work that needs to be completed.

Mitigate quality issues

Share product field performance and quality information with engineers in a centralized system to improve designs, identify supplier problems, and make corrections.

Webinar: Improve change management with PLM

In this webinar, you'll learn how product lifecycle management (PLM) can help you take control of change and improve the quality of your products, with capabilities such as closed-loop, linked quality processes from non-conformance to returns to ECRs and ECOs; configurable workflows to track and record changes to product designs as they happen; built-in reporting to analyze trends in quality metrics to prevent failures before they occur; and more.

Discover PLM

Discover more benefits of product lifecycle management by taking a PLM business assessment.

Get started with product lifecycle management

Thank you for your interest.

Fill out the form to speak with a product expert about how to get started with product lifecycle management.